Easy to Plate® is Vianord Engineering’s fully integrated, modular solution designed to simplify and automate the entire flexographic plate production process. By combining key steps—such as washing, drying, light finishing, and, with the Fusion configuration, imaging and LED exposing—into a seamless, fully automated workflow, Easy to Plate® helps increase productivity, minimise handling errors, and ensure consistent plate quality, all within a cleaner, safer working environment. This advanced solution is ideal for companies aiming to optimise production, enhance efficiency, and improve safety through state-of-the-art automation.

Easy-to-Plate®

Base Modules

Light-Finisher/Stacker

Automatic Dryer

Incremental or Batch Processor

Easy to Plate® Configurations

These configurations can be purchased all at once; or can be reached by upgrading an existing stand-alone processor with the Automatic Dryer module; and/or the Light Finisher/Stacker module.

Designed for fully automated and efficient plate processing, the Easy to Plate® system streamlines different stages of production in different configurations.

With a modular design, customers can invest in a complete automatic line or upgrade it step by step. Equipped with advanced monitoring technology, including internal and remote-access cameras, as well as remote diagnostic tools, the system enhances process control while reducing handling risks.

Additionally, it prevents direct contact with solvent and fumes during standard operations, ensuring a safer and cleaner working environment.

Easy to Plate®

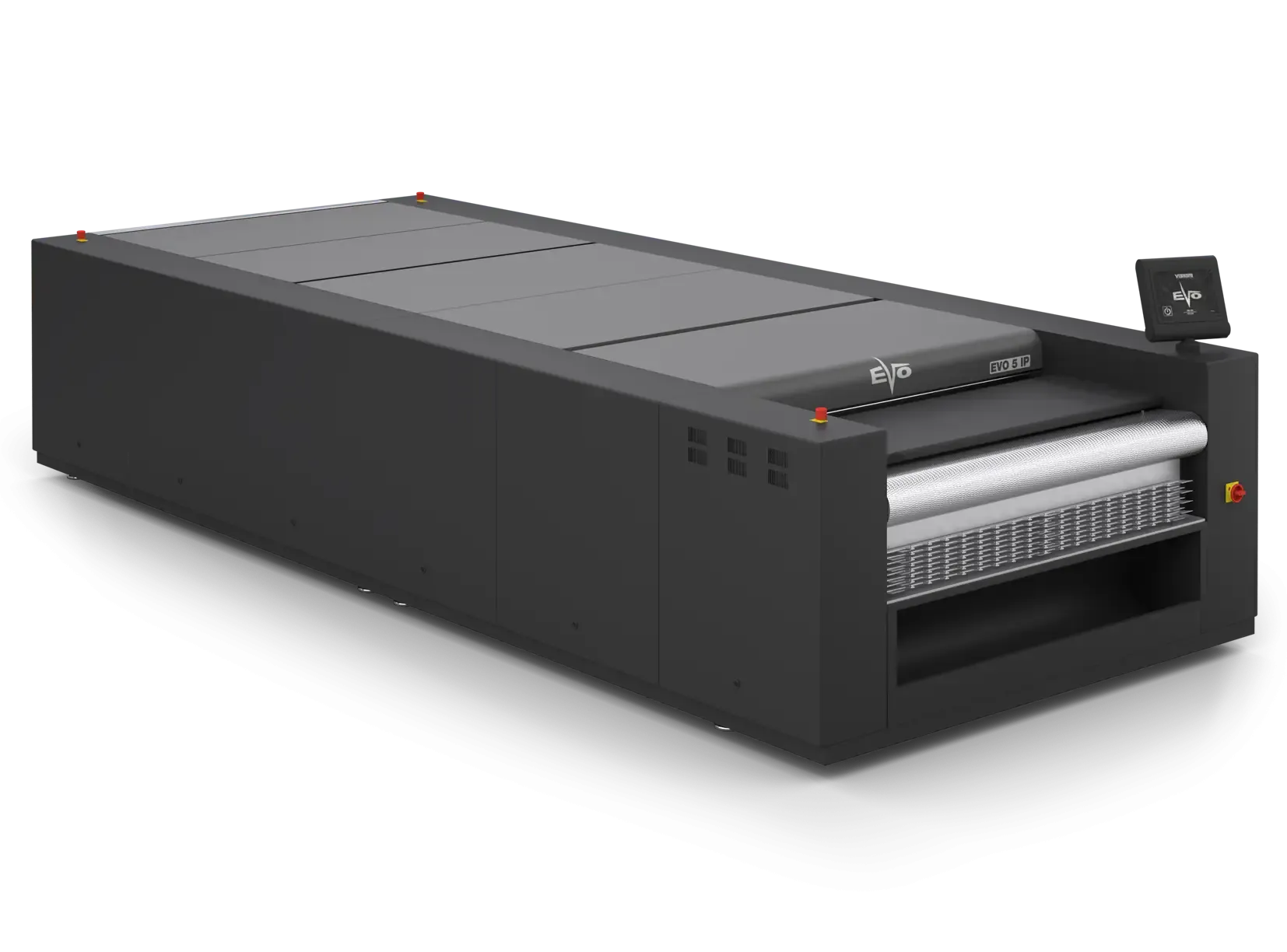

EVO IPI or BPI

Incremental or Batch Processor + Dryer + Light-Finisher/Stacker

Evo Common Features

- Remote access included

- Active component visualisation during the process

- Manual function to run the components separately (Service only)

- Plate process parameters memory (up to 24 channels)

- Programmable warm up / switch off

Smart Entry Section

- Roll plate storage for safe handling and immediate readiness

- Pin bar storage for up to 8 pin bars

- Automatic rollaway punch with programmable punch count

- External punch included with Evo 3 IP

Washout Section

- Separate pre-wash to prevent solvent contamination with LAMS layer

- 2 pre-wash & 8 (Evo 3 IP), 10 (Evo 4-5 IP) and 22 (Evo 4-5 BP) brushes, dedicated cleaning, wiping, and back cleaning brushes

- Oscillating and rotating movements

- 3D Brush Motion, smooth start and reduced vibrations

- Automatic brush oscillation realignment

- Precise solid content analysis

- Automatic solvent replenishment with programmable fresh solvent control

- Adjustable Fresh solvent flow regulation

- Constant preset solvent temperature

- Upgraded cleaning and wiping system

- Integrated exhaust system

- Extended plate handling support for easy removal

- Improved pin bar drop tray to minimize solvent drips

Automatic Dryer Section

- Intelligent system for auto-positioning the nearest drawer

- Live Plate Control with internal camera and flat screen

- 60° Celsius hot air

- 8 drawers

- 4 sections with independent control (2 drawers per section)

- Uniform temperature distribution

- Safety thermostat in every section

- Integrated exhaust system

- Exhaust control with built-in safety mechanism

Light Finisher-Stacker Section

- 1 drawer for UVA + UVC lamps for post exposure and light finishing

- Programmable operation: simultaneous/separate/sequential

- Independent timers for UVA and UVC

- Air flow cooling system

- Automatic plate cooling with programmable time

- Fiber optics for lamp failure detection

- integrated exhaust system

- 8 drawers for stacking finished plates

Next step

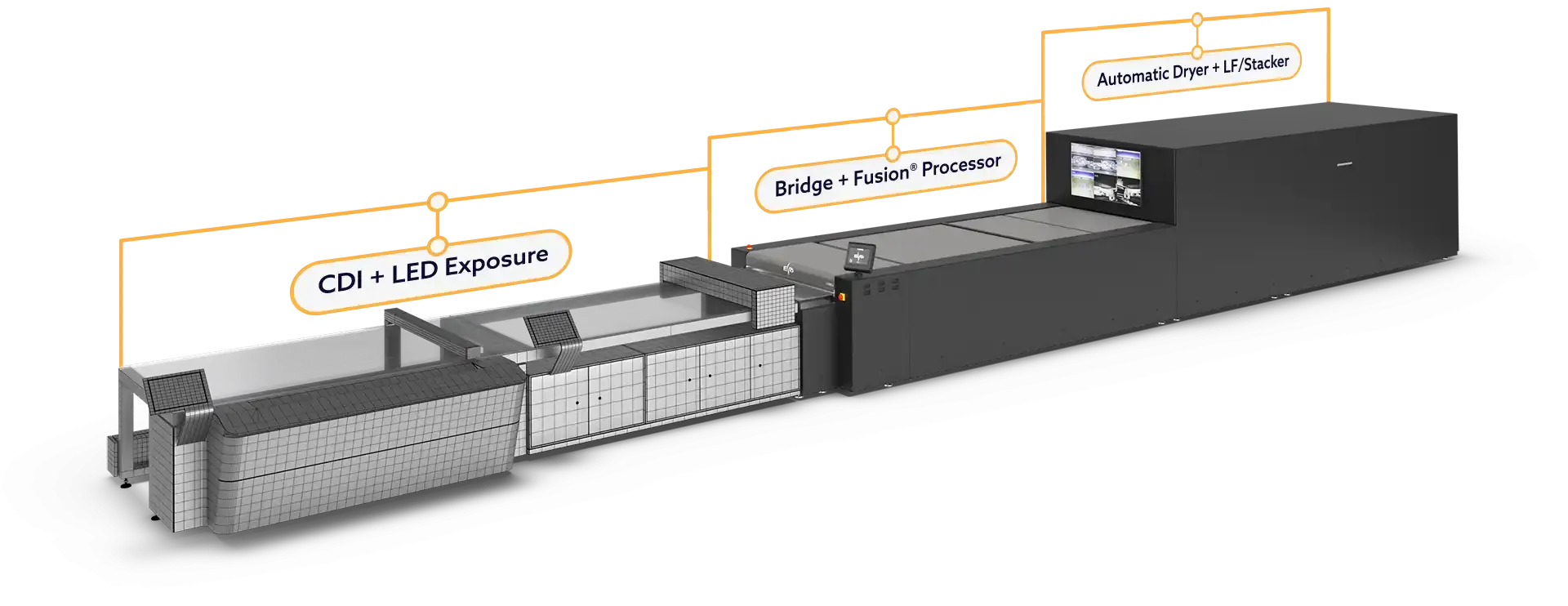

Fusion®

Modular| Scalable | Efficient

Fusion® brings next-level efficiency to flexo plate processing. Its modular design lets you upgrade step by step, transforming your existing setup into a fully automated, high-performance line — exactly when you're ready.

Fusion® Bridge

Incremental or Batch Fusion® Processor

Fusion® Configuration

Designed for fully automated and efficient plate processing, the Fusion® system expands the Easy to Plate concept by integrating imaging and exposing technologies to complete the entire production cycle.

With a modular design, customers can invest in a complete automatic line or upgrade it step by step. Equipped with advanced monitoring technology, including internal and remote-access cameras, as well as remote diagnostic tools, the system enhances process control while reducing handling risks.

Additionally, it prevents direct contact with solvent and fumes during standard operations, ensuring a safer and cleaner working environment.

Evo Common Features

- Remote access included

- Active component visualisation during the process

- Manual function to run the components separately (Service only)

- Plate process parameters memory (up to 24 channels)

- Programmable warm up / switch off

Automatic Entry Section

- Bridge for plate reception, alignment, and transfer

- Lateral pin bar storage with auto-retrieval

- Fully automatic plate punching, pin bar retrieval, and clamping

Washout Section

- Separate pre-wash to prevent solvent contamination with LAMS layer

- 2 pre-wash & 8 (Evo 3 IP), 10 (Evo 4-5 IP) and 22 (Evo 4-5 BP) brushes, dedicated cleaning, wiping, and back cleaning brushes

- Oscillating and rotating movements

- 3D Brush Motion, smooth start and reduced vibrations

- Automatic brush oscillation realignment

- Precise solid content analysis

- Automatic solvent replenishment with programmable fresh solvent control

- Adjustable Fresh solvent flow regulation

- Constant preset solvent temperature

- Upgraded cleaning and wiping system

- Integrated exhaust system

- Extended plate handling support for easy removal

- Improved pin bar drop tray to minimize solvent drips

Automatic Dryer Section

- Intelligent system for auto-positioning the nearest drawer

- Live Plate Control with internal camera and flat screen

- 60° Celsius hot air

- 8 drawers

- 4 sections with independent control (2 drawers per section)

- Uniform temperature distribution

- Safety thermostat in every section

- Integrated exhaust system

- Exhaust control with built-in safety mechanism

Light Finisher-Stacker Section

- 1 drawer for UVA + UVC lamps for post exposure and light finishing

- Programmable operation: simultaneous/separate/sequential

- Independent timers for UVA and UVC

- Air flow cooling system

- Automatic plate cooling with programmable time

- Fiber optics for lamp failure detection

- integrated exhaust system

- 8 drawers for stacking finished plates